When I was working on the tools many many years ago we never gave a thought to the QC controls processes the membrane had gone through before it arrived on site. As long as it rolled out relatively straight and welded OK, that was all we were concerned about.

It wasn’t until I started working for IKO 12 years ago and became directly involved with the manufacturing process that I truly appreciated all of the quality controls that are put in place to ensure that grade A material arrives on site.

At IKO, we work to a set of family values, two of which are performance and long term. These particular values are very important when we look at the products we manufacture at the Clay Cross production facility. The products must be of the highest standard providing long term performance and value to our customers.

From testing of the raw materials, all the way through to the membrane being loaded for delivery, there are countless controls in place.

A selection of the QC checks includes:

Batches are taken from the raw material pellets and processed through our lab, our extruder checking that the torque, pressure and visual appearance are within specification.

At the start of the production process in-line sensors monitor the profile of the sheet (thickness) across its width of the sheet ensuring that is within specification. Inevitably the membrane is generally manufactured slightly thicker than it needs to be.

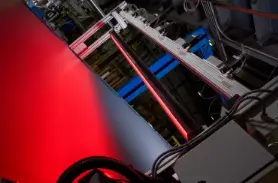

As the membrane travels further down the line it passes under our vision system which is a bank of state of the art highly sensitive video cameras that identify any potential quality issues with the membrane. The footage is recorded, saved and can be accessed at a later date if required.

At the final stage of the manufacturing process the membrane is printed with a QR code, this enables traceability for the membrane prior to, during, and after installation.

The QR code is linked with the vision system data which enables us to replay the video footage of the membrane being manufactured should an issue be found.

A number of manual checks are also carried out during the manufacturing process, which include checking the width of the membrane sheet, thickness & colour. Even though the colour of the membrane does not affect the performance of the material it is very important to the customer. Samples are taken every 30mins and checked against the colour specification.

Being the market leader in the UK we would be expected to have the necessary accreditation such as ISO 9001 Quality Management and ISO 14001 Environmental Management. We have also been accredited with BES 6001 Responsible Sourcing.

Our membranes are also independently accredited by the British Board of Agrement (BBA). This confirms our performance regarding fire, wind – uplift and durability as well as many other physical and mechanical properties. The BBA certificate states that our membrane should last ‘in excess of 30 years’ on all of our membranes. We also carry out our own internal durability testing and we have products which have been on our facility roof for many years and are tested frequently using our accelerated aging/weathering equipment.

We don’t just sell to the UK flat roofing market we also export to over 20 countries and have obtained the necessary accreditation required for each country. We are regularly audited and have at least one audit a month at our Clay Cross site.

So the next time you unroll one of our membranes, you will appreciate that quality doesn’t just happen!

For more information, please contact IKO Polymeric’s technical team.

Phone: 01257 488 012