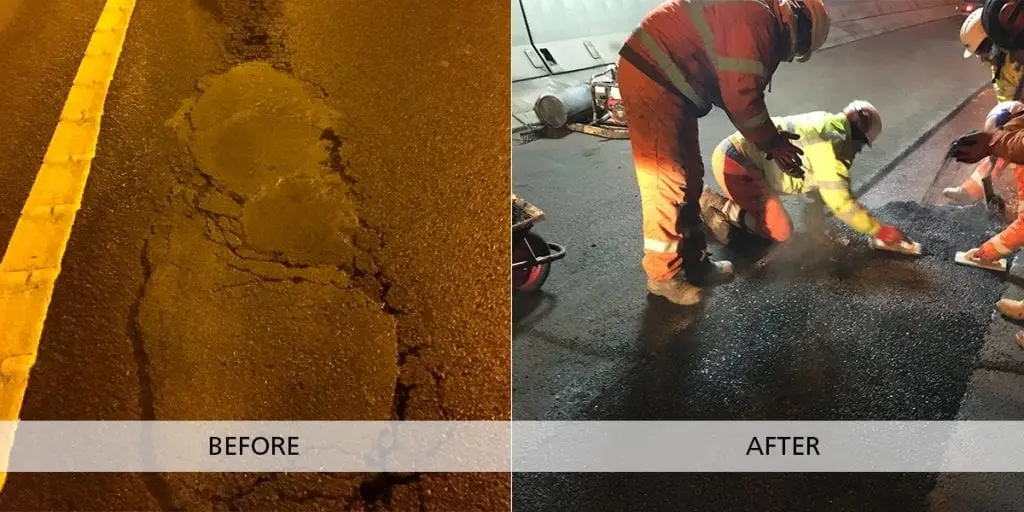

All too often, road repairs are let down by the use of products that fail to offer the longevity required. Polymer modified Mastic Asphalt addresses those longevity concerns and has established itself as the material of choice for highways repairs and bridge surfacing projects.

Mastic Asphalt is a traditional construction material, ideal for hard-wearing surfaces and offering excellent waterproofing properties.

Consisting of limestone aggregates bound in asphaltic cement, polymer modification was introduced in the 1980s and the technology of its production continues to develop to meet modern specification and installation demands.

What makes Mastic Asphalt ideal for highways and road infrastructure repair?

Mastic Asphalt provides a durable, voidless and consistent wearing surface with a long service life. It can be laid quickly, keeping road closures and disruption to a minimum. It also outlasts other highways repair materials – so individual project costs are kept down, and total life cycle costs minimised too.

While nobody doubts the environmental challenge we face in the number of vehicles on our roads and our use of fossil fuels, an immediate priority is to keep roads in as good a condition as possible and running as smoothly as possible.

When the road surface is in good condition, traffic can flow freely and run efficiently. There’s a reduced risk to vehicles – either of breakdowns that contribute to congestion and increased emissions, or of damage to tyres, suspension or exhausts that can impact a vehicle’s efficiency.

As well as crack repairs, Mastic Asphalt is suitable for type 2 expansion joints, transitional joint details where carriageway materials change, reinstating carriageways around street ironworks and also complete bridge deck surfacing projects.

IKO’s Permatrack Mastic Asphalt System offers all of these speed and cost benefits. The polymer modified asphalt doesn’t require mechanical compaction to achieve a specific void content.

It is a hot applied flowable voidless product, which cools quickly so it can take standing traffic sooner, it bonds to a variety of substrates, and it accommodates differential movement.

The high modulus surface means the material holds a certain amount of stiffness, providing resistance to rutting while also provides flexibility to meet movement demands associated with large volumes of traffic. Skid resistance is provided by rolling precoated chippings into the surface whilst the material is still hot.

What other benefits does IKO Permatrack Mastic Asphalt offer?

Third party certification remains an important aspect of product manufacture in the construction and highways industries. Independent testing and approval give valuable peace of mind to the professionals specifying and installing a product and highways resurfacing and repairing is no exception.

The Highways Authority Product Approval Scheme (HAPAS) uses the testing expertise of the British Board of Agrément (BBA) to certify products for the highways industry. IKO Permatrack is no exception, having been tested and certified under certificate number 02/H072.

IKO has also taken the steps to get IKO Permatrack products CE Marked in accordance with BS EN 13108-6:2006. The European Standard specifies requirements for mixtures of the mix group Mastic Asphalt for use on roads, airfields, and other trafficked areas.

Beyond the general environmental benefits of keeping roads free of traffic jams, IKO also demonstrate further sustainability credentials through their membership of CO2balance’s CarbonZero scheme.

Every tonne of Mastic Asphalt that IKO produce is offset by internationally approved carbon credits, which means that all highways and road infrastructure projects help to fund humanitarian and environmental projects – including providing stoves to families in Kenya and boreholes to communities in Uganda.

IKO Permatrack was used to make repairs to the M25 London orbital motorway; more details about that project are available here. For more information about IKO Permatrack, download our brochure here or contact us to discuss your project.