Single Ply membranes over the last 50 years have always been credited with being flexible and able to cope with the vast majority of roofing details or challenges put in front of them, especially PVC & TPE membranes.

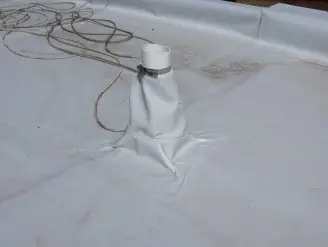

However, we have all had that impossible detail where the builder has placed a pipe detail up close to an upstand; or a redundant piece of steel work that doesn’t appear to be doing anything but needs to be sealed against or a detail which is just an awkward shape.

We have attempted to weather it to the best of our ability but it isn’t 100% watertight or just didn’t look as good as we had hoped.

With the development and introduction of Liquid systems, liquid waterproofing has become a welcome accessory to the Single Ply manufacturer’s portfolio and is often thought of as a “get out of jail” card for those awkward uncompromising details.

Care should be taken that the liquid polymer that you are using is supplied by the manufacturer of the single ply membrane or approved by the manufacturer. This will ensure that there are no issues with compatibility between the polymer waterproofing and single ply membrane and that any guarantees are not compromised.

IKO Polymeric’s liquid offer is a high build polyurethane embedment coat incorporating moisture triggered curing system that forms the base of the IKO Polimar UV system. With excellent fluid properties for ease of application, this provides a high build, high solids coat that offers superb adhesion. IKO Polimar UV can be applied to a wide range of substrates and facilitates excellent detailing in complex areas.

IKO Polimar UV is available in two standard colours mid grey and slate grey which is in line with our standard membrane colours and comes with the following accessories:

IKO PVC Refurbishment Primer – used to prepare the Armourplan PVC membrane surface.

IKO Ruberseal Tape primer – used to prepare the Spectraplan TPE membrane surface.

100gsm reinforcement GRF strip – used to reinforce joints and gaps etc.

GP primer – used to prepare porous substrates.

MC activator and Base – used to prepare metal substrates.

More information can be found on IKO Polimar UV Liquid Detailing page.

So if you are installing an IKO Polymeric system and have a difficult detail that you are not 100% confident in waterproofing or the aesthetics aren’t up to your usual standards then consider using our IKO Polimar liquid detailing.

It’s not cheating!

For more information, please contact IKO Polymeric’s technical team.

Phone: 01257 488 012