Membrane lined gutters have now been used in the roofing and cladding industry for many years. These can be in the form of single skin, insulated and composite gutter systems.

When designed and installed correctly, membrane lined gutters provide a secure watertight gutter solution especially at the gutter joints which historically have been the weakest point where bolted joints relied upon sealants and gaskets.

Having a fully welded waterproof joint has eliminated these problems, making industrial gutters much more reliable and effective.

IKO Polymeric supply factory laminated membrane coated steel for gutter fabrication in several grades depending on the gutter design and required service life.

The membrane thickness has a direct impact on the expected service life of the gutter, the durability of the membrane and the guarantee period. As standard IKO Polymeric offers a 0.6mm and 1.2mm thick membrane option depending on the system requirements.

The Single Ply Membrane Association (SPRA) gives guidance on this subject in the SPRA Component Quality Standard for Factory Manufactured Single Ply Membrane Gutters which is available to download at www.spra.co.uk

IKO Polymeric offers galvanised steel substrates thicknesses ranging from 0.6mm to 1.5mm with steel widths up to 1.475m wide.

This offers gutter manufacturers and fabricators a full choice of products to enable them to select the correct material depending on whether they are supplying a high drainage capacity composite gutter or a small single skin design.

IKO Armourflow

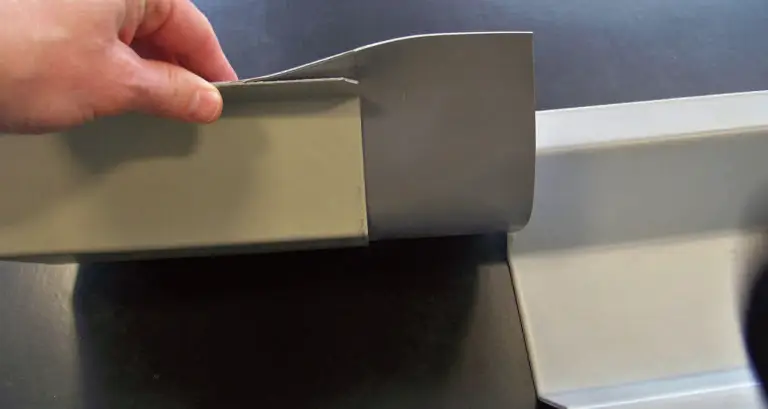

IKO Polymeric also offers IKO Armourflow metal which is 1.2mm thick galvanised steel substrate laminated with a 1.2mm Armourplan membrane. IKO Armourflow differs from standard pre-coated metal as it incorporates a 75mm membrane flap at one sheet end.

This allows a quicker installation time as there is only one weld to carry out per joint. It also reduces cost for materials as no membrane jointing strip is needed and as there is only one weld, it decreases the chances of workmanship errors leading to leaks.

IKO Armourfold

IKO Armourfold’s bespoke gutter lining system is an ideal solution for your gutter refurbishment. Using a combination of 0.6mm steel and 1.2mm Armourplan membrane, IKO Armourfold offers a quick and simple option to the more traditional systems.

IKO Armourfold can be used in any sector but lends itself to commercial and industrial gutters refurbishments that require long lengths of gutter to be waterproofed and guaranteed. The 50mm overlap allows for sheets to be welded together offering a homogeneous, watertight weld that can be guaranteed for up to 25 years.

The bespoke design ensures that IKO Armourfold will fit into almost any gutter shape and with 3m lengths, IKO Armourfold can also be easily moved around site. Click here to download the product flyer to find out more.

To ensure a completely watertight and guaranteed system is achieved, IKO Polymeric also offers a full range of flow tested rainwater outlets tested to BSI – BS EN 1256. IKO outlets ensure that the hot air welded seal between the rainwater outlet and the coated metal is 100% watertight.

They don’t rely on sealants that are a maintenance item which will ultimately fail. IKO Polymeric also offers a full range of accessories such as preformed corners, membrane strips and even bespoke details for complex situations.

When designing a gutter, in addition to the rainfall capacity requirement and the sizing of the rainwater outlets needed to drain the roof area; the structural loadings, live, dead and snow, should be taken into consideration.

Large girth gutters may need additional structural support. Gutter maintenance should also be considered: is the gutter a practical width to walk down or easily use a soft brush in? These are the questions that need answering in advance.

If you want to find more about IKO Armourflow or IKO Armourfold, or have any other gutter related enquiries on a project that you are working on, please contact your IKO Area Business Manager who would be happy to assist further.