Mastic asphalt is a durable, hard-wearing, moisture-resistant material. Capable of offering a service life of at least 50 years, mastic asphalt is suitable for a variety of applications, including flooring, flat roofing and car park decks and structures.

It is also one of the oldest construction materials, and modern variants offer the same performance and longevity with up-to-date production methods and quality control. With the leadership demonstrated by the mastic asphalt industry regarding environmental impact, it is a material popular with specifiers and contractors alike.

What applications is Mastic Asphalt suitable for?

As part of the building fabric, mastic asphalt can provide a durable ground floor surface or a resilient flat roof waterproofing solution.

Its seamless, voidless composition means it is as resistant to ground moisture in a floor as it is to rainwater on a roof.

For areas affected by radon gas, it can also act as a gas barrier in a floor. And because mastic asphalt has no water content, it cures quickly – meaning it can be ready to receive a floor finish within a matter of hours or installed on a roof within a relatively tight time window.

Suitable for use in projects of all types and sizes, including domestic buildings, mastic asphalt really comes into its own in commercial and industrial applications.

A high level of fatigue resistance means the right grade of material can bear the stress of vehicle movements, whether forklift trucks on a warehouse floor or cars, vans, and lorries on a car park roof deck.

Flat roofs can feature mastic asphalt as waterproofing whether the roof deck is insulated or not. Where thermal insulation is present, it can be used in both conventional and inverted warm roof constructions.

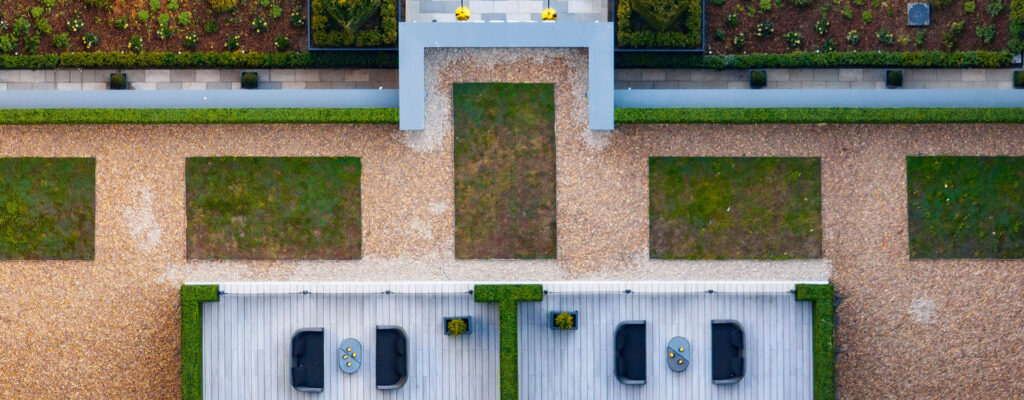

Again, as long as an appropriate grade of asphalt is used, the roof can take light foot traffic or vehicle movements and can also be specified as a green roof or garden roof.

Being virtually non-combustible, mastic asphalt also offers the benefits of no significant flame spread and no flame penetration, which is particularly critical for flat roof specification. And while it is laid molten, asphalt requires no naked flame, thereby addressing what can be a critical requirement of product specifications.

Below ground, mastic asphalt can be used as a tanking solution on the outside of basement structures. There is no reaction through contact with the ground, and the asphalt again provides an impervious protection to the basement structure.

The qualities of mastic asphalt also mean it is suitable for use in highways and civil engineering projects, whether as a surfacing material, in expansion joints, or for reinstating ironworks.

What is polymer modified Mastic Asphalt?

Adding polymers to traditional mastic asphalt formulations retains all the benefits of the material while helping to improve some of those key qualities – including durability, temperature stability and fatigue resistance.

Polymer modification is part of extensive research and development into mastic asphalt to ensure that it is both traditional and familiar as a material, while fully capable of meeting the demands of modern specification and construction.

It is most likely to feature in flat roofing solutions, where the direct exposure to weather and temperature cycles makes installation quality and product performance particularly critical.

What are the environmental benefits of Mastic Asphalt?

Mastic asphalt is made from aggregate mixed into bitumen. Recognising the energy use and carbon emissions associated with its production, the mastic asphalt industry collaborated to achieve a world first: in 2008, the industry collectively achieved the CarbonZero standard.

Stakeholders in the mastic asphalt industry seek to reduce their environmental impact as much as possible, then work with schemes like CO2balance to offset their remaining carbon emissions. The aim is for mastic asphalt to be a carbon neutral solution.

Mastic asphalt can also be recycled once it has reached the end of its useful life in a project, meaning specifiers can consider how it might be ‘reclaimed’ as part of a building ‘deconstruction’.

Its durability – which can be 50 or 60 years or more, if the building requires it – means little or no maintenance is required, and the whole-life cost of mastic asphalt is lower than alternative flooring or waterproofing solutions.

IKO produce a range of mastic asphalt solutions – including IKO Floorstar, IKO Permapark, IKO Permascreed, IKO Roofstar and IKO Tankstar – for the range of applications described in this post. Find out more about IKO solutions for commercial projects, contact us for sales or technical information, or view our range of technical support services.