Use of adhesives in winter months

The winter months pose various issues for roofing trades especially when installing adhered single ply membrane systems.

Generally, both PU adhesives and contact adhesives are not recommended to be used if the temperature is below 5° C, leaving the roofing contractor with no choice other than changing the system to a mechanically fastened specification or waiting for the temperature to rise enough to use the adhesives.

However, a mechanically fixed roofing system might not always be the best solution for the project, perhaps the building is a swimming pool where the internal high humidity conditions mean an adhered system is more appropriate.

Additionally, we all know that time is of the essence in modern construction and waiting around for the right conditions to install is never a good option. Mostly the answer is yes, but each project should be taken on its own merits.

IKO Polymeric has launched a brand-new adhesive ideal for cold winter days. IKOpro PUMA Zero adhesive can be applied at temperatures as low as 0 °C and used for adhering both insulation boards and fleece-backed single ply membranes.

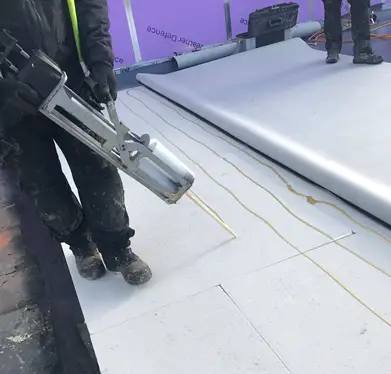

The adhesive contains no solvents and cures in minutes, making the installation quick and easy for the roofing contractor by also providing significant labour savings. IKOpro PUMA Zero adhesive is dispensed through a battery powered applicator assuring on-ratio mixing of the two-part adhesive and provides a high-quality, consistent application every time.

In addition to the lower than normal operating temperature the IKOpro PUMA Zero has other great benefits that can be gained all year round. As the adhesive is strip bonded rather than applying adhesive using the traditional roller or squeegee applied methods the application is very quick.

This seems like a new way of gluing membrane to substrates however this has been the ‘norm’ in the US for years, one of our initial worries was seeing a ghosting effect of the adhesive beads through the membrane.

However, our fears were soon put to rest as once the membrane surface is rolled over with a weighted roller to spread the adhesive beads, they are virtually unnoticeable.

In addition, the adhesive can be used for applying the membrane as well as bonding thermal insulation boards to a bituminous VCL or bonding multiple layers together, making the product a one stop solution where traditionally separate adhesive types would be required for each application.

IKO PUMA Zero adhesive application

You should ensure the substrate is clean and dry. Eliminate uneven surfaces to ensure positive contact between the substrate, adhesive, and insulation board or membrane.

Prior to use the adhesive cartridges should be conditioned to achieve a temperature of 18 ⁰C, this can be achieved by storing the adhesive cartridges overnight in a heated room or by using site applied hot air.

Attach a mixing nozzle to the threaded mixing head, taking care to prevent adhesive from mixing before use by keeping the cartridge upright and place the cartridge into the applicator.

The applicator guns are very robust and come with an additional battery and a fast charger that take about half an hour to re-charge a depleted battery. As well as selling the applicator guns, we also hire them out to customers to make the process more cost effective for those trying the product for the first time.

Apply IKOpro PUMA Zero adhesive directly to the substrate, using 10mm-15mm beads as per the project specific wind load calculation pattern to achieve proper coverage rates for required uplift performance. Allow adhesive to begin to foam, normally 1-2 minutes, and roll the fleece backed membrane into wet adhesive or place insulation boards.

Roll the surface of the waterproofing membrane with a weighted roller to ensure positive contact between the membrane, the adhesive, and the substrate. This increases the adhesive footprint (bead width) and minimises ghosting of the adhesive ribbon pattern through the membrane.

IKOpro PUMA Zero adhesive is designed to give the contractor about 6 minutes of open time on a normal summer day so the membrane must be positioned and rolled quickly. The adhesive open time will be shorter on very hot, humid days and longer on cold, dry days

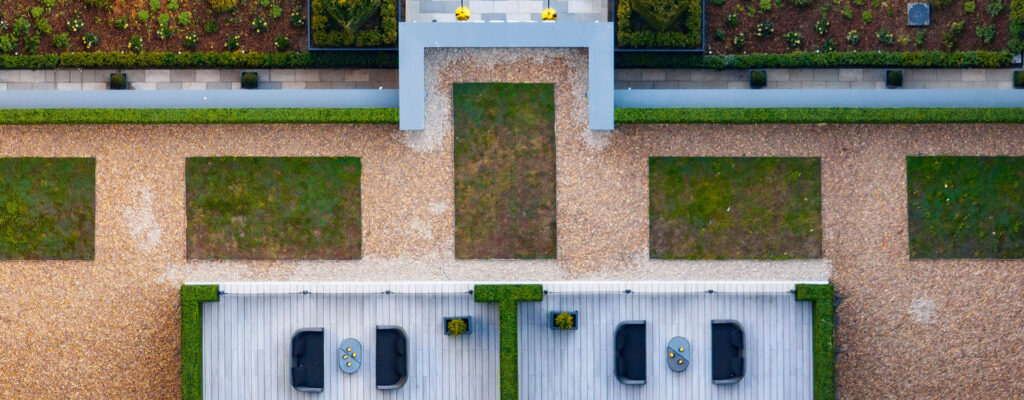

Overview of the completed application after the membrane is laid.

So in summary, if cold weather is holding your installation up, and you would like the convenience of using one product for multiple applications and improved installation time, please contact your local Business Manager or Technical Services department.

Email: [email protected]